Description

Feature:

1. Long vacuum maintenance time. 31 days after vacuum evacuation, the degree of vacuum change is less than 6%.

2. Imported high-quality polycarbonate injection molding.

3. Avoid using sealing grease. The top and bottom parts of the vessel are sealed with high-quality silicone rubber O-rings.

4. A flat retaining ring on the top of the vessel makes it easy to hold. When the top plug is sealed, it can cooperate with the ring-shaped protrusion at the bottom to stably stack multiple.

5. There is a conical threaded hole on the top and the side of the base. The valve can be screwed and fixed on any screw hole. The other screw hole is equipped with a vacuum gauge, which is convenient for accurately understanding the vacuum status in the container at any time, and can also be sealed with a wire plug.

6. The valve core is made of precision metal materials, and the air intake flow is gradually and gradually adjusted from small to large.

7. After the ball valve is tightened slightly with your fingers, the air leakage is zero under one atmospheric pressure.

8. Ball valve and air pipe are connected by quick-change joint. Its connector can rotate 360 degrees freely, and the air pipe adopts imported soft nylon tube.

9. Two ball valves can be installed at the same time, one for evacuation and one for introducing inert gas to realize vacuum preservation under inert gas atmosphere.

Parameter:

Product Name:Plastic Vacuum Dryer

Main Material: Polycarbonate

Sealing Ring Material: O-Type Silicone Rubber Sealing Ring

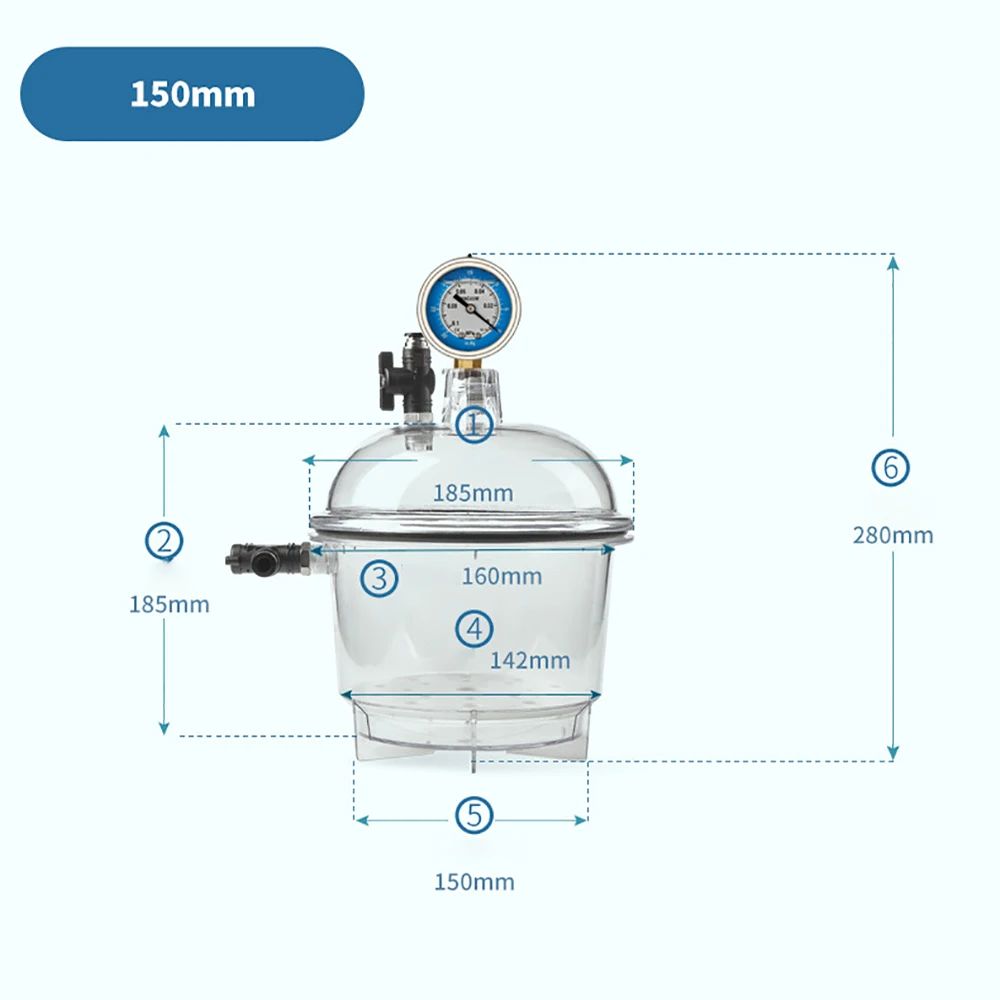

Inner Diameter: 150MM

Outer Diameter: 185MM

Partition Diameter: 142MM

Total Height: 280MM

Ambient Temperature: -40~120°C

Valve Interface Diameter: 8MM

Vacuum Maintenance Time: About 100 Days

Application:

1. Vacuum storage: suitable for vacuum dry storage of biochemical reagents, medicines, optical lenses, precision components, seeds, cultural relics and other items. Dry storage under vacuum can greatly extend the storage time. The transparent container makes it easy to observe the storage status of the items placed inside.

2. Vacuum storage of inert gas: Anti-oxidation of materials.

3. Vacuum drying: The vacuum drying process is fast and safe, and it is especially effective for drying volatile liquids.

Niam Mullins –

–

Valtena Amodei –

–

Emma Carra –

Germain Beaumont –